Russian Lathe: The Epitome Of Precision And Versatility

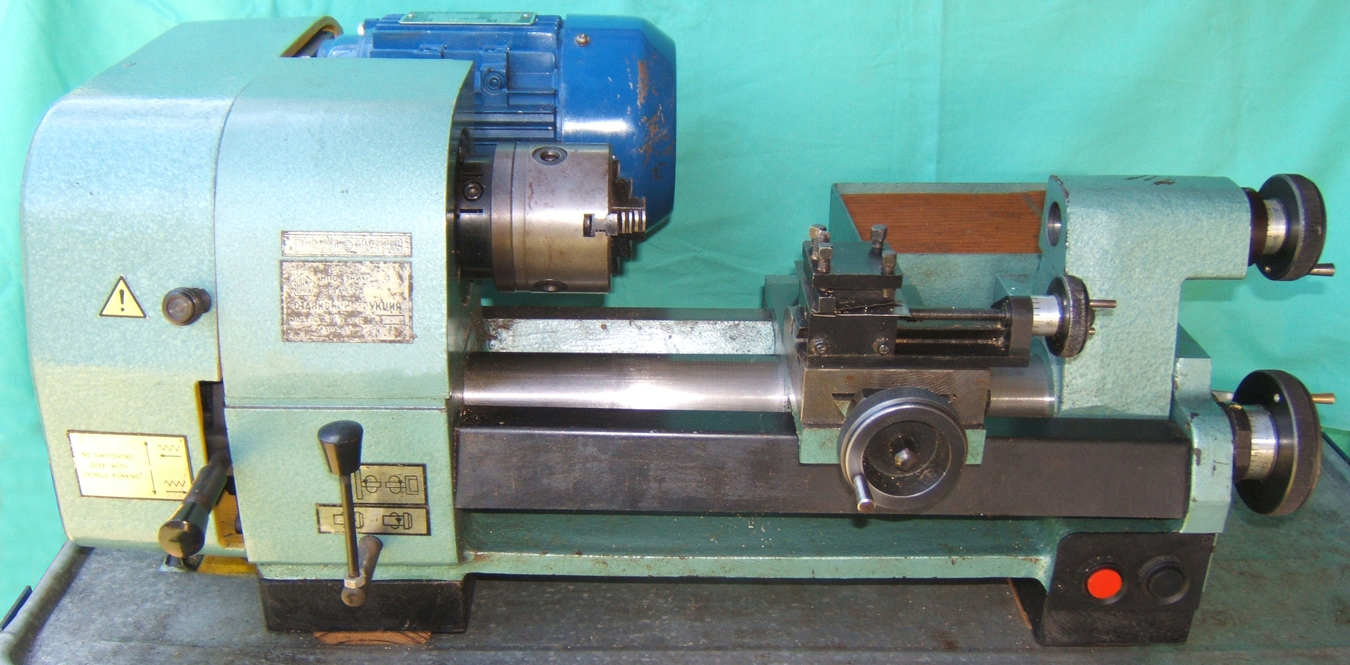

A Russian lathe, often known as a screw-cutting lathe, is a metalworking machine used to shape metal workpieces by rotating them against a cutting tool. A famous example of a Russian lathe is the 1K62, which was developed in the Soviet Union in the 1960s and is still widely used today.

Russian lathes are renowned for their durability, accuracy, and versatility. They are capable of performing a wide range of operations, including turning, facing, drilling, boring, and threading. One significant historical development in the field of Russian lathes was the invention of the lead screw in the 15th century, which allowed for more precise control over the cutting tool.

In this article, we will explore the various types of Russian lathes, their capabilities, and their applications in various industries.

- How To Open Bath And Body Works Hand Soap

- Why Does Tiktok Say No Internet Connection

- Breckie Hill Shower Leak Video

- Breckie Hill Shower Video Leak

- Antonio Brown Megan

Russian Lathe

Russian lathes are renowned for their durability, accuracy, and versatility, making them essential for various metalworking applications. Key aspects to consider when exploring Russian lathes include:

- Construction: Durable and robust design

- Accuracy: High precision and repeatability

- Versatility: Wide range of operations

- Capacity: Different sizes and capacities

- Controls: Manual, semi-automatic, or CNC

- Accessories: Variety of attachments and tooling

- Applications: Machining, repair, and manufacturing

- History: Originating from Russian innovation

- Popularity: Widely used in industries worldwide

- Availability: Easily accessible from various suppliers

These aspects are interconnected and contribute to the overall value and effectiveness of Russian lathes. Their durability ensures longevity and reliability, while their accuracy and versatility enable precise and efficient machining operations. The wide range of accessories and attachments further enhances their capabilities, making them suitable for diverse applications. Understanding these key aspects is crucial for selecting and using Russian lathes effectively.

Construction

The construction of Russian lathes is renowned for its durability and robust design, contributing significantly to their longevity and reliability in demanding metalworking environments. This durability encompasses various facets, including:

- Dd Osama Brothers

- Is Ddot And Dd Osama Brothers

- Nomi And Mac Miller

- Influencer Guillermo

- Buffet De Mariscos Near Me

- Heavy-duty frame: The lathe's frame is typically made of cast iron or steel, providing a solid foundation for the machine and absorbing vibrations during operation, ensuring stability and accuracy.

- Precision-ground bed: The bed, where the workpiece is mounted, is precision-ground to ensure a smooth and level surface, facilitating precise linear movement and minimizing friction.

- Hardened and ground gears: The lathe's gears are hardened and ground to resist wear and tear, ensuring smooth and precise operation, even under heavy loads.

- Rigid headstock and tailstock: The headstock and tailstock, which hold the workpiece and cutting tool respectively, are rigidly constructed to minimize deflection and maintain alignment during machining, resulting in accurate and consistent results.

Collectively, these design elements contribute to the exceptional durability and robustness of Russian lathes, making them well-suited for heavy-duty applications and ensuring longevity in demanding industrial environments.

Accuracy

Accuracy, encompassing high precision and repeatability, is a defining characteristic of Russian lathes. This accuracy translates into the ability to produce consistent, high-quality parts, meeting precise specifications and tolerances. Several key aspects contribute to the exceptional accuracy of Russian lathes:

- Precision components: Russian lathes incorporate high-precision components, such as precision bearings, lead screws, and measuring instruments. These components are manufactured to exacting standards, ensuring minimal backlash and maintaining tight tolerances during operation.

- Rigid construction: The rigid and robust construction of Russian lathes minimizes deflection and vibration, providing a stable platform for precise machining. This rigidity is achieved through the use of heavy-duty materials, such as cast iron and steel, and precision-machined surfaces.

- Advanced control systems: Modern Russian lathes often feature advanced control systems, including CNC (computer numerical control) and DNC (direct numerical control). These systems allow for precise control over the lathe's movements and parameters, resulting in highly accurate and repeatable machining operations.

- Skilled operators: While the precision of Russian lathes is a significant factor, the skill and experience of the operator also play a crucial role in achieving accurate results. Trained operators are adept at setting up and operating the lathe, ensuring proper alignment and utilizing appropriate cutting techniques.

The high precision and repeatability of Russian lathes are essential for various applications, including the production of precision parts, such as those used in aerospace, medical devices, and manufacturing equipment. These qualities make Russian lathes a valuable asset in industries that demand accuracy, reliability, and consistent quality.

Versatility

Versatility is a key characteristic of Russian lathes, enabling them to perform a diverse range of operations and cater to various machining needs. This versatility stems from several key facets, each contributing to the lathe's overall adaptability and functionality.

- Turning: Russian lathes excel at turning operations, which involve rotating the workpiece while a cutting tool shapes its outer diameter, inner diameter, or both. This process is fundamental to metalworking and allows for the creation of cylindrical or conical parts.

- Facing: Facing operations utilize Russian lathes to create flat surfaces on the ends of workpieces. This process is crucial for preparing surfaces for further machining or assembly, ensuring perpendicularity and precision.

- Drilling: Drilling operations involve using Russian lathes to create holes in workpieces. The lathe's spindle provides rotational motion to the drill bit, while the workpiece is moved along the lathe's axis to create precise and aligned holes.

- Threading: Russian lathes are capable of threading operations, which involve cutting helical grooves into workpieces to create threads. This process is essential for creating fasteners, such as bolts and nuts, as well as for connecting pipes and other components.

The versatility of Russian lathes makes them indispensable in various industries, including manufacturing, automotive, aerospace, and general engineering. Their ability to perform multiple operations with high precision and efficiency contributes to their popularity and widespread use across the globe.

Capacity

The capacity of Russian lathes refers to their ability to handle workpieces of different sizes and dimensions. This capacity is a critical component of Russian lathes, as it determines the range of applications for which they are suitable. Russian lathes are available in a wide range of capacities, from small benchtop models to large industrial machines, each designed to accommodate specific workpiece sizes and requirements.

The capacity of a Russian lathe is typically defined by the maximum diameter and length of the workpiece that it can accommodate. The maximum diameter refers to the largest diameter of a workpiece that can be turned on the lathe, while the maximum length refers to the longest workpiece that can be accommodated between the lathe's headstock and tailstock. The capacity of a Russian lathe is also affected by the power of its motor, as well as the rigidity and stability of its construction.

The capacity of a Russian lathe is an important consideration when selecting a machine for a particular application. For example, a small benchtop lathe may be suitable for hobbyists or small workshops, while a large industrial lathe may be required for heavy-duty applications in large-scale manufacturing environments. Understanding the capacity of a Russian lathe is essential for ensuring that the machine is capable of handling the intended workpieces and meeting the specific requirements of the application.

In summary, the capacity of Russian lathes is a critical component that determines their suitability for different applications. By considering the maximum diameter and length of the workpieces that can be accommodated, as well as the power and rigidity of the machine, users can select a Russian lathe that meets their specific needs and ensures optimal performance.

Controls

The advent of advanced control systems, such as manual, semi-automatic, or CNC (Computer Numerical Control), has had a profound impact on the capabilities and applications of Russian lathes. These control systems play a critical role in automating various aspects of lathe operation, from simple tasks to complex machining processes, resulting in enhanced precision, efficiency, and productivity.

In manual control mode, the operator has complete control over the lathe's movements and functions, relying on their skill and experience to guide the cutting tool. While this mode provides maximum flexibility and allows for fine adjustments, it can be time-consuming and requires a high level of operator expertise. Semi-automatic control, on the other hand, combines manual operation with automated functions, such as automatic tool changes or spindle speed control. This mode offers a balance between operator control and automation, reducing cycle times while maintaining a degree of flexibility.

CNC control represents the highest level of automation, where the lathe is programmed to follow a predefined set of instructions. The program controls all aspects of the lathe's operation, including tool selection, feed rates, and cutting parameters. CNC lathes offer unparalleled precision, repeatability, and efficiency, making them ideal for high-volume production and complex machining operations. They also minimize human error and reduce the need for highly skilled operators.

The choice of control system for a Russian lathe depends on the specific application and the desired level of automation. For small-batch production or prototype development, manual or semi-automatic control may be sufficient. However, for high-volume production or complex machining tasks, CNC control offers significant advantages in terms of speed, accuracy, and consistency.

Accessories

The array of accessories, attachments, and tooling available for Russian lathes significantly expands their capabilities, enabling them to perform a wide range of machining tasks with precision and efficiency. These accessories enhance the lathe's versatility and allow for customization to meet specific application requirements.

- Tool holders: Tool holders securely grip cutting tools and allow for quick and easy tool changes, minimizing downtime and increasing productivity.

- Chucks: Chucks are used to hold the workpiece in place and provide rotational motion. Different types of chucks, such as three-jaw chucks and four-jaw chucks, accommodate various workpiece shapes and sizes.

- Steady rests: Steady rests provide additional support to long or slender workpieces, preventing deflection and ensuring stability during machining operations.

- Tailstocks: Tailstocks provide support to the workpiece from the rear and can be used for drilling, reaming, and other operations that require axial alignment.

The availability of these accessories makes Russian lathes highly adaptable and suitable for various applications, from simple turning operations to complex machining tasks. The ability to customize the lathe with specific accessories allows for tailored solutions that meet the demands of different industries and machining requirements.

Applications

Russian lathes are indispensable tools in various industries due to their extensive range of applications, primarily in machining, repair, and manufacturing. Machining encompasses a wide array of processes that involve shaping and cutting metal workpieces to create intricate components. Russian lathes excel in this domain, performing operations such as turning, facing, drilling, and threading with high precision and efficiency.

In repair applications, Russian lathes play a crucial role in restoring damaged or worn metal parts. Their versatility allows for precise resurfacing, resizing, and rethreading of components, extending their lifespan and reducing downtime in various industries, including automotive, aerospace, and heavy machinery.

Furthermore, Russian lathes are integral to manufacturing processes, enabling the production of high-quality metal parts for a vast array of industries. From automotive components and medical devices to aerospace parts and consumer electronics, Russian lathes contribute to the creation of precision-engineered products with intricate designs and tight tolerances.

Understanding the applications of Russian lathes in machining, repair, and manufacturing is crucial for optimizing their use and maximizing their capabilities. This knowledge enables businesses to select the most appropriate lathe for their specific requirements, ensuring efficient and cost-effective production. Moreover, it highlights the versatility and adaptability of Russian lathes, making them a valuable asset in diverse industrial settings.

History

The history of Russian lathes is deeply intertwined with Russian innovation, which has played a pivotal role in shaping the development and capabilities of these machines. Russian engineers and inventors have consistently pushed the boundaries of lathe technology, introducing groundbreaking innovations that have transformed the metalworking industry.

One of the most significant contributions of Russian innovation to the development of lathes is the invention of the lead screw in the 15th century. This innovation enabled the lathe to cut threads with greater precision and repeatability, revolutionizing the production of precision components. Another notable contribution is the development of the turret lathe in the 19th century, which allowed for faster and more efficient machining of complex parts by eliminating the need to manually change tools.

In the 20th century, Russian innovation continued to drive the advancement of lathes. The development of CNC (Computer Numerical Control) technology in the 1950s revolutionized lathe operation, enabling highly precise and automated machining processes. Russian engineers also played a key role in the development of advanced materials and cutting tools, further enhancing the capabilities and performance of lathes.

The practical applications of understanding the connection between Russian innovation and Russian lathes are numerous. By recognizing the historical roots and innovative spirit behind these machines, users can appreciate their inherent capabilities and potential. This understanding can guide decision-making when selecting and operating Russian lathes, maximizing their effectiveness and unlocking their full potential in diverse industrial applications.

Popularity

Russian lathes have gained immense popularity and widespread use across a diverse range of industries worldwide due to their exceptional capabilities and versatility. The connection between their popularity and their inherent qualities is tightly intertwined, with each aspect reinforcing the other.

One of the primary reasons for the popularity of Russian lathes is their exceptional durability and reliability. These machines are built to withstand demanding working conditions and heavy-duty applications, ensuring longevity and minimizing downtime in industrial settings. Their robust construction and high-quality components contribute to their ability to handle continuous use and challenging machining tasks effectively.

Moreover, the versatility of Russian lathes further enhances their popularity. Their ability to perform a wide range of operations, including turning, facing, drilling, and threading, makes them indispensable in various industries. This versatility reduces the need for multiple specialized machines, streamlining production processes and increasing efficiency. The ability to customize Russian lathes with a range of accessories and tooling further expands their versatility, allowing them to adapt to specific machining requirements.

In summary, the popularity of Russian lathes is deeply rooted in their exceptional durability, reliability, and versatility. By understanding this connection, industries can make informed decisions when selecting and utilizing Russian lathes, maximizing their productivity and efficiency. Furthermore, it highlights the global recognition of Russian innovation and engineering excellence in the field of metalworking.

Availability

The availability of Russian lathes from a wide range of suppliers is a crucial aspect that contributes to their popularity and accessibility in the global market. This easy accessibility offers numerous advantages and implications for the manufacturing and metalworking industries.

- Global Presence: Russian lathes are manufactured and supplied by companies located in various countries worldwide. This global presence ensures that businesses can easily find and purchase these machines from local or international suppliers, reducing lead times and shipping costs.

- Diverse Selection: The availability of Russian lathes from multiple suppliers provides a diverse selection of models and specifications. Customers can choose from a range of sizes, capacities, and features to match their specific requirements and applications.

- Competitive Pricing: The presence of multiple suppliers fosters competition in the market, leading to competitive pricing and favorable purchasing terms. Businesses can compare prices and negotiate with different suppliers to secure the best deals.

- Reliable Supply Chain: A well-established supply chain network ensures that Russian lathes are readily available when needed. This reliability minimizes disruptions in production schedules and helps businesses maintain operational efficiency.

Overall, the easy accessibility of Russian lathes from various suppliers contributes to their widespread adoption and use across industries. It allows businesses to easily find and purchase the right machines for their needs, ensuring timely delivery, competitive pricing, and a reliable supply chain. This availability plays a significant role in the overall success and productivity of the manufacturing and metalworking sectors.

In conclusion, our exploration of the "Russian lathe" has provided valuable insights into the capabilities, applications, and significance of these remarkable machines. Key takeaways include their exceptional durability, versatility, and precision, making them indispensable tools in various industries worldwide. The availability of Russian lathes from multiple suppliers ensures easy accessibility and competitive pricing, contributing to their widespread adoption.

As technology continues to advance, we can expect further innovations in Russian lathes, enhancing their capabilities and efficiency. The integration of advanced control systems, automation, and cutting-edge materials promises to revolutionize the metalworking industry. By embracing these advancements and leveraging the strengths of Russian lathes, businesses can unlock new possibilities and drive productivity to unprecedented levels.

- Can Pregnant Women Drink Bloom

- Template How We See Each Other

- Florida Baseball Coach Scandal

- Khamzat Chimaev With And Without Beard

- What Is Ddot Real Name

Continued

Used 1992 ryazan Ryazan Tough Russian Lathe Precision Lathes in

Russian lathe Gorki SP 16K02 (sold) YouTube