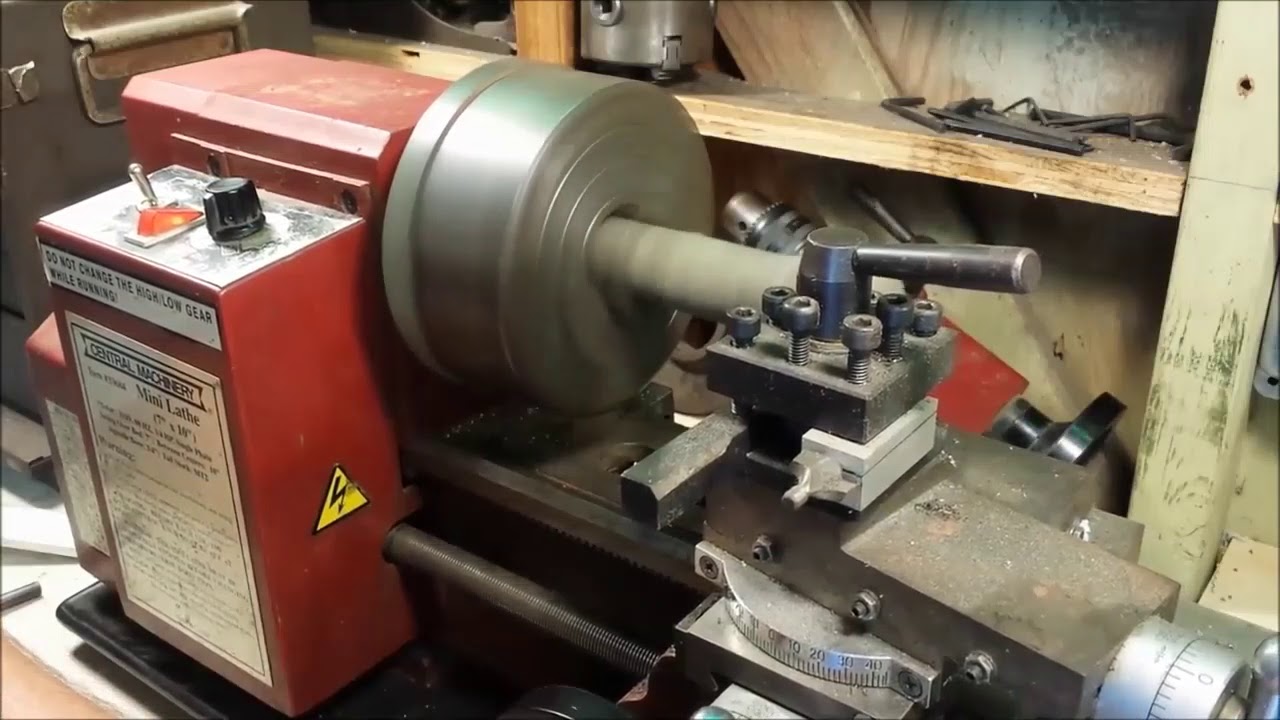

Lathe Accidents: Prevention And Safety Best Practices

Lathe accidents, defined as dangerous incidents involving machines that rotate materials to shape or cut them, remain a concern in workplace settings. One example is the 2018 case where a worker's hand was caught in a lathe, resulting in severe injuries.

Understanding lathe accidents is crucial because they can lead to severe injuries and have significant consequences for individuals, businesses, and the economy. Historically, technological advancements such as machine guards and automation have been made to enhance safety, but accidents continue to occur.

This article will explore the types, causes, and preventive measures for lathe accidents, providing valuable information for employers, employees, and safety professionals to minimize risks and promote a safer working environment.

- Teacher Crying At Wedding

- Dd Osama Brothers

- Breckie Hill Showers

- What The French Toast Commercial

- Darren Barnet Britney Spears

Lathe Accidents

Lathe accidents are a major concern in many industries. They can result in serious injuries or even death. It is important to be aware of the key aspects of lathe accidents in order to prevent them from happening.

- Types of lathe accidents

- Causes of lathe accidents

- Consequences of lathe accidents

- Prevention of lathe accidents

- Training and education on lathe safety

- Roles and responsibilities in lathe safety

- Legal and regulatory aspects of lathe safety

- Technological advancements in lathe safety

- Best practices in lathe safety

These key aspects provide a comprehensive overview of the topic of lathe accidents. By understanding these aspects, employers and employees can take steps to prevent these accidents from happening and ensure a safe working environment.

Types of lathe accidents

Understanding the different types of lathe accidents is crucial for developing effective prevention strategies. These accidents can vary in severity and nature, involving different machine components and resulting in distinct injuries.

- What Is Dd Osama Real Name

- Khazmat Without Beard

- Breckue Hill Shower Vid

- Khamzat Chimaev Bald

- Why Did Bunnie Fire Haley

- Caught-in accidents

Occur when body parts or clothing become trapped between rotating parts of the lathe, such as the chuck or spindle, leading to crushing or amputation injuries.

- Struck-by accidents

Involve being hit by flying debris or ejected materials from the lathe, such as chips or broken tools, causing lacerations, impact injuries, or eye damage.

- Pinch-point accidents

Occur when fingers or hands are caught between the lathe carriage and the workpiece or tool, resulting in crushing or pinching injuries.

- Electrical accidents

Can happen due to faulty wiring, improper grounding, or contact with live electrical components, leading to shocks, burns, or electrocution.

These types of lathe accidents highlight the diverse hazards associated with lathe operation and underscore the need for proper training, machine guarding, and adherence to safety protocols to prevent these incidents and ensure a safe working environment.

Causes of lathe accidents

Understanding the causes of lathe accidents is paramount to developing effective preventive measures and ensuring workplace safety. Various factors can contribute to these incidents, ranging from human error to mechanical failures and environmental conditions.

- Machine-related causes

Defective or poorly maintained machinery, inadequate guarding, or improper setup can lead to accidents. For instance, a worn chuck could cause a workpiece to come loose, resulting in a caught-in accident.

- Human factors

Operator error, fatigue, lack of training, or failure to follow safety protocols can increase the risk of accidents. Examples include starting the lathe without securing the workpiece or reaching over rotating parts.

- Environmental factors

Poor lighting, slippery floors, or excessive noise levels can create a hazardous work environment and contribute to accidents. For example, poor lighting can make it difficult to see potential hazards, leading to contact with rotating parts.

- Material-related causes

Improper workpiece selection or handling can cause accidents. Using the wrong type of material or failing to secure it properly could result in breakage or ejection, leading to struck-by accidents.

These causes highlight the multifaceted nature of lathe accidents and emphasize the importance of a comprehensive approach to prevention. Addressing these factors through proper machine maintenance, thorough training, a safe work environment, and appropriate material selection can significantly reduce the risk of lathe accidents and promote a safe workplace.

Consequences of lathe accidents

Lathe accidents can have severe consequences for individuals, businesses, and the economy. These consequences can range from physical injuries to financial losses and legal liabilities.

- Physical Injuries

Lathe accidents can cause a variety of physical injuries, including cuts, lacerations, amputations, and crush injuries. These injuries can lead to permanent disability or even death.

- Financial Losses

Lathe accidents can result in significant financial losses for businesses. These losses can include medical expenses, lost productivity, and damage to equipment.

- Legal Liabilities

Businesses can be held legally liable for lathe accidents that occur on their premises. These liabilities can include workers' compensation claims, lawsuits, and fines.

- Other Consequences

Lathe accidents can also have other consequences, such as damage to the company's reputation and decreased employee morale.

The consequences of lathe accidents can be severe and far-reaching. It is important for businesses to take steps to prevent these accidents from happening and to have a plan in place to respond to them if they do occur.

Prevention of lathe accidents

Preventing lathe accidents is critical to ensuring a safe and productive work environment. Effective prevention measures aim to eliminate or minimize the risks associated with lathe operations, thereby reducing the likelihood of accidents occurring.

The connection between prevention and lathe accidents is evident in the cause-and-effect relationship between the two. By identifying and addressing the factors that contribute to lathe accidents, such as inadequate machine guarding, improper use, and lack of training, preventive measures can effectively mitigate these risks. For instance, installing proper guarding around rotating parts can prevent caught-in accidents, while providing comprehensive training on safe lathe operation can reduce human errors.

Real-life examples further illustrate the importance of prevention. In a study of lathe accidents in the manufacturing industry, it was found that nearly half of the accidents could have been prevented with proper machine guarding. Similarly, a survey of lathe operators revealed that those who received regular safety training had a significantly lower risk of being involved in an accident.

Understanding the connection between prevention and lathe accidents has practical applications in workplace safety. By implementing comprehensive prevention programs that incorporate engineering controls, work practices, and training, employers can create a safer work environment, reduce the risk of accidents, and protect their employees from harm. This not only benefits individual workers but also contributes to a more efficient and productive workplace.

Training and education on lathe safety

Training and education on lathe safety play a crucial role in preventing lathe accidents and ensuring a safe work environment. It encompasses various aspects that empower individuals with the knowledge, skills, and awareness necessary to operate lathes safely and minimize the risk of accidents.

- Machine Familiarization

Understanding different lathe components, their functions, and potential hazards is essential for safe operation. - Safe Work Practices

Training on proper setup, workpiece handling, tool selection, and emergency procedures helps prevent accidents. - Hazard Recognition and Avoidance

Recognizing potential hazards, such as rotating parts, exposed belts, and flying debris, and knowing how to avoid them is critical. - Personal Protective Equipment (PPE)

Understanding the importance of wearing appropriate PPE, such as safety glasses, gloves, and hearing protection, and using it correctly is crucial for personal safety.

Comprehensive training and education on lathe safety empower individuals to identify and mitigate risks, fostering a culture of safety in the workplace. It reduces the likelihood of accidents, protects workers from injuries, and promotes a safe and productive work environment. Investing in training and education is not only a moral obligation but also a sound business decision, as it can prevent costly accidents, reduce downtime, and improve overall productivity.

Roles and responsibilities in lathe safety

In the context of lathe accidents, understanding and fulfilling roles and responsibilities is paramount to preventing incidents and ensuring a safe work environment. These roles and responsibilities encompass various aspects, each playing a crucial part in mitigating risks and fostering a culture of safety.

- Machine Maintenance

Ensuring proper maintenance of lathes, including regular inspections, lubrication, and repairs, is essential to prevent accidents caused by mechanical failures.

- Operator Training

Providing comprehensive training to lathe operators on safe work practices, hazard recognition, and emergency procedures empowers them to operate lathes safely and minimize risks.

- Supervision and Oversight

Supervisors play a vital role in enforcing safety protocols, monitoring operator behavior, and ensuring compliance with established safety standards.

- Workplace Culture

Fostering a positive safety culture where employees feel comfortable reporting hazards, sharing concerns, and actively participating in safety initiatives is crucial for accident prevention.

By clearly defining and fulfilling these roles and responsibilities, organizations can create a robust safety system that minimizes the risk of lathe accidents. This not only protects workers from injuries but also contributes to a more efficient and productive work environment.

Legal and regulatory aspects of lathe safety

Understanding the legal and regulatory aspects of lathe safety is crucial because they establish a framework for preventing lathe accidents and protecting workers from harm. These regulations outline the minimum safety standards that must be met to ensure the safe operation of lathes in workplaces.

When legal and regulatory requirements are not followed or enforced, it can increase the risk of lathe accidents. For example, if a lathe is not properly guarded or maintained, it can lead to accidents such as entanglement, amputation, or eye injuries. Employers who fail to comply with safety regulations may face legal consequences, including fines, penalties, and even criminal charges in the event of a serious accident.

Conversely, when legal and regulatory aspects are effectively implemented and enforced, they can significantly reduce the occurrence of lathe accidents. For instance, regular inspections and maintenance of lathes, as mandated by regulations, help identify and address potential hazards before they cause accidents. Additionally, providing proper training to operators on safe work practices, as required by regulations, empowers them to operate lathes safely and avoid accidents.

In conclusion, the legal and regulatory aspects of lathe safety play a critical role in preventing lathe accidents and ensuring a safe work environment. By establishing clear safety standards, providing a framework for enforcement, and promoting a culture of compliance, legal and regulatory measures help protect workers from harm and contribute to a more productive and efficient workplace.

Technological advancements in lathe safety

Technological advancements have played a crucial role in enhancing lathe safety, minimizing the risk of accidents, and improving the overall safety of lathe operations. These advancements encompass various aspects, ranging from improved machine designs to sophisticated safety features, all contributing to a safer work environment.

- Machine guarding

Advanced machine guarding systems, such as interlocks and light curtains, prevent operators from coming into contact with hazardous areas of the lathe, reducing the risk of entanglement or amputation injuries.

- Emergency stop mechanisms

Lathes now incorporate sensitive emergency stop mechanisms that can quickly halt the machine's operation in the event of an emergency, minimizing the severity of accidents.

- Automated safety features

Modern lathes often incorporate automated safety features, such as automatic chuck clamping and spindle braking, which enhance safety by eliminating the need for manual intervention in potentially hazardous situations.

- Improved materials and designs

Advancements in materials and designs have led to stronger and more durable lathe components, reducing the likelihood of catastrophic failures that could cause accidents.

These technological advancements have significantly contributed to reducing the occurrence and severity of lathe accidents. By incorporating these features into lathes, manufacturers and employers can create a safer work environment, protect workers from harm, and improve the overall efficiency and productivity of lathe operations.

Best practices in lathe safety

Best practices in lathe safety are crucial to preventing lathe accidents and ensuring a safe work environment. These practices encompass a range of measures, including proper machine guarding, regular maintenance, and operator training, all aimed at minimizing the risks associated with lathe operations.

Understanding the connection between best practices in lathe safety and lathe accidents is vital. Lathe accidents often occur due to inadequate safety measures, such as missing or malfunctioning machine guards, improper maintenance, or lack of operator training. By implementing best practices, these risks can be significantly reduced, thereby preventing accidents and protecting workers from harm.

Real-life examples demonstrate the effectiveness of best practices in lathe safety. In one instance, a lathe operator sustained severe injuries when their hand came into contact with a rotating chuck due to a missing safety guard. In another case, a poorly maintained lathe malfunctioned, causing a workpiece to fly off and strike a worker. These accidents could have been prevented if proper safety measures had been in place.

The practical applications of understanding the connection between best practices in lathe safety and lathe accidents are numerous. By adhering to these practices, employers can create a safer work environment, reduce the risk of accidents, and protect their employees from injuries. Additionally, it can improve productivity and efficiency by minimizing downtime caused by accidents and promoting a positive safety culture in the workplace.

In conclusion, this article has explored various aspects of lathe accidents, examining their causes, consequences, and prevention. Key insights include the significance of machine guarding, regular maintenance, operator training, and adherence to best practices in minimizing the risks associated with lathe operations. Understanding the interconnections between these factors is crucial for developing effective accident prevention strategies and ensuring a safe work environment.

To prevent lathe accidents and protect workers from harm, a comprehensive approach is necessary, encompassing engineering controls, safe work practices, and a strong safety culture. Employers have a responsibility to implement and enforce safety standards, while employees must be adequately trained and follow established protocols. By working together, we can create safer workplaces and reduce the incidence of lathe accidents.

- Is Lana Rhoades Pregnant

- Khamzat Chimaev Without Bear

- Brown Easley

- When Is Peysoh Getting Out Of Jail

- Taylor Swift Cry

WATCH Real video of lathe machine incident, What is a lathe machine

Russian Lathe Accident A Case Study in Workplace Safety Centre News

Lathe accident YouTube