Lathe Accident Prevention: Essential Guide For Workplace Safety

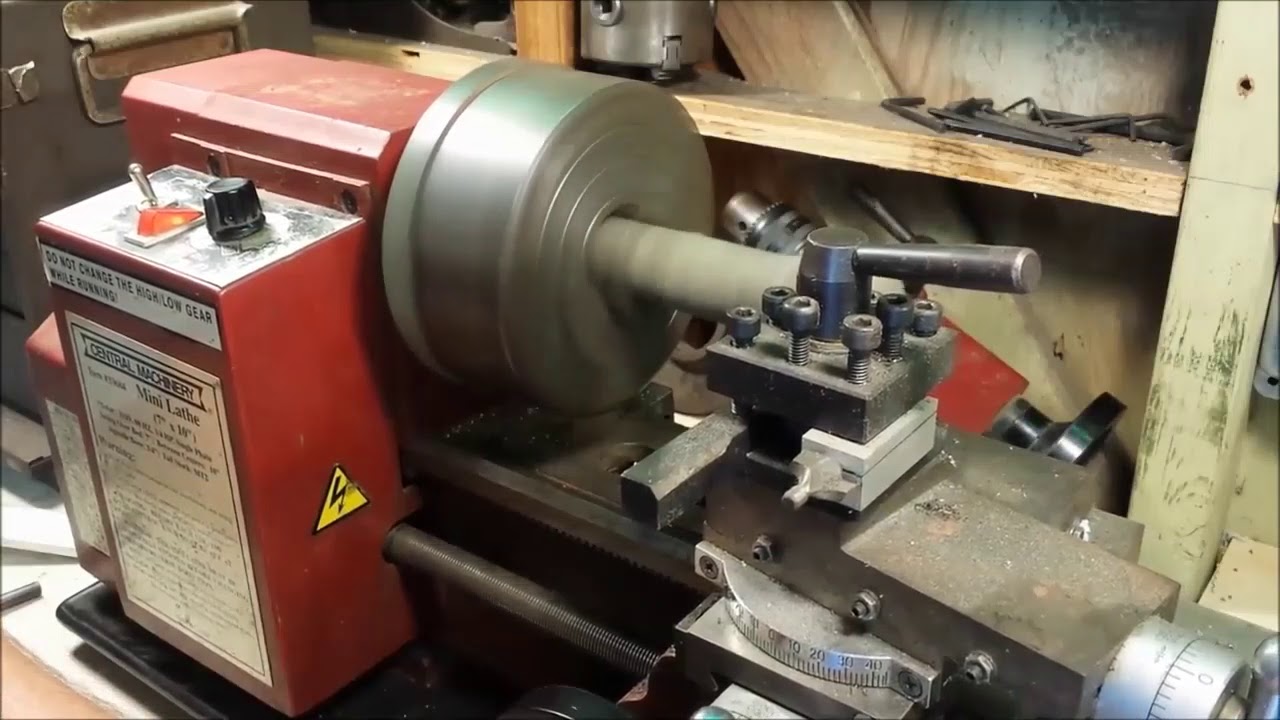

A lathe accident is a severe incident involving a lathe, a machine used to shape metal or wood. Tragically, these accidents can result in catastrophic injuries, including amputations and other life-altering outcomes. For instance, in a recent factory incident, an operator suffered a devastating hand injury when their hand became entangled in a rapidly spinning lathe.

Understanding lathe accidents is crucial for enhancing workplace safety. They highlight the significance of implementing robust safety measures, adhering to proper operating procedures, and providing comprehensive training to operators. Historically, the invention of the automatic lathe in the late 19th century revolutionized lathe safety by reducing the risk of accidents.

As we delve into this article, we will explore the causes, consequences, and preventive measures associated with lathe accidents. Our focus will encompass industry best practices, regulatory frameworks, and innovative technologies aimed at minimizing their occurrence and safeguarding the well-being of workers.

- Hisashi Ochi

- Why Did Bunnie Fire Haley

- Can Pregnant Women Drink Bloom

- Breckie Hill Showers

- Baja Blast Pie

Lathe Accident

Understanding the essential aspects of a lathe accident is paramount for enhancing workplace safety and preventing catastrophic injuries. These aspects encompass various dimensions related to the causes, consequences, and preventive measures associated with lathe accidents.

- Causes

- Consequences

- Prevention

- Safety measures

- Training

- Regulation

- Technology

- Industry best practices

- Risk assessment

- Emergency response

A thorough understanding of these aspects enables us to identify potential hazards, develop effective control measures, and create a safe work environment for lathe operators. By exploring these key areas, we can gain deeper insights into the complexities of lathe accidents and work towards their prevention.

Causes

Understanding the causes of lathe accidents is essential for developing effective prevention strategies. These accidents can result from a multitude of factors, including:

- Khamzat Beard

- Jenna Ortega Net Worth

- Skip The Games El Paso Texas

- Brian Easely

- Brian Easley Daughter Now

- Mechanical failure

Malfunctioning or poorly maintained lathe equipment can lead to accidents. For instance, a worn-out chuck can cause a workpiece to fly off the lathe, posing a serious hazard to the operator.

- Human error

Operator error, such as improper setup or neglecting to follow safety procedures, is a common cause of lathe accidents. Fatigue, inattention, and lack of training can also contribute to human error.

- Environmental factors

Poor lighting, inadequate ventilation, and slippery floors can create an unsafe work environment and increase the risk of accidents.

- Inadequate training

Operators who are not properly trained on the safe operation of lathes are more likely to cause accidents. Training should cover topics such as machine setup, workpiece handling, and emergency procedures.

These factors, acting alone or in combination, can lead to devastating lathe accidents. By identifying and addressing the root causes of these accidents, we can develop and implement effective preventive measures and create a safer work environment for lathe operators.

Consequences

The consequences of a lathe accident can be severe and life-altering. These consequences can be both physical and psychological, impacting the victim's health, well-being, and ability to work. Understanding the consequences of lathe accidents is crucial for developing effective prevention strategies and ensuring the safety of lathe operators.

Physical consequences of lathe accidents can range from minor cuts and bruises to severe injuries such as amputations, crush injuries, and eye damage. The severity of the injury depends on factors such as the type of lathe, the workpiece being machined, and the personal protective equipment worn by the operator. In some cases, lathe accidents can be fatal.

Psychological consequences of lathe accidents can be just as devastating as physical injuries. Victims may experience post-traumatic stress disorder (PTSD), anxiety, depression, and other mental health issues. These psychological consequences can make it difficult for victims to return to work or engage in other activities they once enjoyed.

Understanding the consequences of lathe accidents is essential for developing effective prevention strategies. By identifying and addressing the hazards associated with lathes, we can reduce the risk of accidents and protect the health and well-being of lathe operators.

Prevention

Prevention plays a critical role in minimizing the occurrence and severity of lathe accidents. By identifying and addressing potential hazards, implementing appropriate control measures, and promoting a culture of safety, we can create a safer work environment for lathe operators. Prevention is not merely a component of lathe accident; it is the foundation upon which a comprehensive safety program is built.

Real-life examples abound, demonstrating the effectiveness of prevention measures in reducing lathe accidents. In one instance, a manufacturing facility implemented a comprehensive training program for lathe operators, covering topics such as machine setup, workpiece handling, and emergency procedures. This training program resulted in a significant decrease in the number of lathe accidents at the facility.

In another example, a lathe manufacturer redesigned its machines to incorporate safety features such as automatic guards and interlocks. These design changes made it more difficult for operators to come into contact with hazardous moving parts, further reducing the risk of accidents.

Understanding the connection between prevention and lathe accident is essential for developing and implementing effective safety strategies. By investing in prevention, we can reduce the incidence of lathe accidents, protect the health and well-being of lathe operators, and ensure the smooth and efficient operation of workplaces.

Safety measures

Safety measures are paramount in the prevention of lathe accidents, safeguarding operators from potential hazards and ensuring a safe working environment. A comprehensive approach to safety incorporates various facets, each playing a crucial role in minimizing the occurrence and severity of lathe accidents.

- Machine guarding

Machine guarding involves the installation of physical barriers or devices to prevent operators from coming into contact with hazardous moving parts of the lathe. This includes guards for the chuck, spindle, and other rotating components. - Personal protective equipment (PPE)

PPE is essential for protecting operators from flying debris, chips, and other hazards. This includes safety glasses, gloves, hearing protection, and appropriate clothing. - Safe work practices

Safe work practices, such as proper setup and operation of the lathe, following established procedures, and maintaining a clean and organized work area, are crucial for preventing lathe accidents. - Training and education

Thorough training and education for lathe operators on machine operation, safety procedures, and emergency response plans are essential for ensuring their safety and competence.

By implementing these safety measures, businesses can create a safer work environment for lathe operators, reducing the risk of accidents and protecting their health and well-being. These measures are not isolated components but interconnected parts of a comprehensive safety program that prioritizes the prevention of lathe accidents and promotes a culture of safety in the workplace.

Training

Training plays a pivotal role in preventing lathe accidents by equipping operators with the knowledge, skills, and attitudes necessary to operate lathes safely and efficiently. Lack of proper training is a major contributing factor to lathe accidents, as operators may not be aware of the potential hazards associated with lathe operation or may not know how to operate the lathe safely.

For example, a study by the National Institute for Occupational Safety and Health (NIOSH) found that over half of lathe accidents were caused by operator error. Of these accidents, many could have been prevented if the operators had received proper training on lathe operation and safety procedures.

Proper training should cover a variety of topics, including lathe setup and operation, workpiece handling, tool selection and use, and emergency procedures. Training should also emphasize the importance of following safety procedures and wearing appropriate personal protective equipment (PPE).

In addition to preventing accidents, proper training can also help to improve productivity and efficiency. Operators who are well-trained on lathe operation are more likely to be able to operate the lathe safely and efficiently, which can lead to increased production and reduced costs.

Regulation

Regulation plays a pivotal role in preventing lathe accidents by establishing minimum safety standards for lathe operation and providing a framework for enforcement. Without proper regulation, employers may be less likely to invest in safety measures, and workers may be less likely to follow safety procedures. As a result, lathe accidents may become more common and more severe.

One of the most important aspects of regulation is the establishment of safety standards. These standards specify the minimum requirements for lathe operation, including the design of the lathe, the use of safety guards, and the training of operators. By following these standards, employers can help to reduce the risk of lathe accidents.

In addition to establishing safety standards, regulation also provides a framework for enforcement. This framework includes inspections, citations, and penalties. By enforcing safety regulations, government agencies can help to ensure that employers are complying with the law and that workers are protected from unsafe working conditions.

The connection between regulation and lathe accidents is clear. Regulation can help to prevent lathe accidents by establishing minimum safety standards and providing a framework for enforcement. By understanding this connection, we can take steps to improve lathe safety and reduce the risk of accidents.

Technology

Technology plays a crucial role in preventing and mitigating lathe accidents by enhancing safety measures, improving machine operation, and providing real-time monitoring capabilities. From advanced guarding systems to predictive maintenance tools, technological advancements have transformed lathe safety, leading to a significant reduction in accident rates.

- Automated Safety Systems

Advanced guarding systems, such as light curtains and laser scanners, create virtual barriers around hazardous areas of the lathe, preventing operators from coming into contact with moving parts. These systems have significantly reduced the risk of severe injuries, including amputations and crush injuries.

- Improved Machine Design

Modern lathes incorporate ergonomic designs and user-friendly interfaces, reducing operator fatigue and minimizing the likelihood of errors. Additionally, improvements in machine stability and vibration control enhance precision and reduce the risk of workpiece accidents.

- Predictive Maintenance

Sensors and diagnostic tools continuously monitor lathe performance, allowing for early detection of potential issues. Predictive maintenance programs identify and address minor problems before they escalate into major failures, preventing catastrophic accidents and unplanned downtime.

- Remote Monitoring and Control

Advanced control systems enable remote monitoring and operation of lathes, allowing operators to maintain a safe distance from hazardous areas. This technology is particularly beneficial in high-risk environments, such as those involving large or heavy workpieces.

The integration of technology into lathe operation has revolutionized safety practices, reducing accidents, improving productivity, and enhancing overall workplace safety. As technology continues to advance, we can expect even greater advancements in lathe safety, further protecting operators and ensuring the safe and efficient operation of these machines.

Industry best practices

Industry best practices play a vital role in preventing lathe accidents and ensuring the safety of operators and workplaces. These practices represent the collective knowledge and experience of industry experts and serve as guidelines for safe lathe operation.

A comprehensive understanding of industry best practices allows organizations to identify and implement effective measures to mitigate risks associated with lathe operations. By adhering to these practices, businesses can minimize the likelihood of accidents, reduce their severity, and create a safer working environment.

Real-life examples of industry best practices in lathe accident prevention include:

- Regular maintenance and inspection of lathes to ensure proper functioning and identify potential hazards.

- Implementation of appropriate guarding systems, such as interlocks, light curtains, and machine covers, to prevent contact with hazardous moving parts.

- Adequate training and supervision of lathe operators on safe work practices, emergency procedures, and proper handling of tools and materials.

- Provision of personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection, to minimize the risk of injuries.

- Establishment of clear operating procedures and work instructions to guide operators and ensure consistent adherence to safety protocols.

Understanding the connection between industry best practices and lathe accident is essential for developing and implementing effective safety strategies. By adopting and promoting these practices, organizations can significantly reduce the occurrence and severity of lathe accidents, safeguarding the well-being of their employees and creating a more productive and efficient work environment.

Risk assessment

Risk assessment plays a critical role in preventing lathe accidents by identifying and evaluating potential hazards and risks associated with lathe operation. Through systematic analysis, organizations can develop effective strategies to mitigate these risks and enhance workplace safety.

- Hazard identification

The initial step involves identifying potential hazards in the lathe operation environment, including mechanical failures, electrical hazards, and ergonomic risks. This comprehensive identification process helps organizations understand the scope of risks and prioritize mitigation measures.

- Risk analysis

Once hazards are identified, their potential risks are analyzed to determine the likelihood and severity of accidents. This analysis considers factors such as the frequency of exposure, the severity of potential injuries, and the effectiveness of existing controls. A systematic approach to risk analysis ensures that all potential risks are thoroughly evaluated.

- Risk evaluation

Based on the risk analysis, risks are evaluated to prioritize mitigation efforts. The evaluation process involves comparing the identified risks against acceptable risk criteria or standards to determine which risks require immediate attention and which can be managed through ongoing monitoring.

- Control measures

To mitigate identified risks, appropriate control measures are implemented. These measures may include engineering controls, such as machine guarding and improved ventilation, administrative controls, such as training and work procedures, and personal protective equipment (PPE).

By conducting thorough risk assessments, organizations can proactively identify and address potential hazards associated with lathe operation. This systematic approach helps prevent lathe accidents, ensures compliance with safety regulations, and creates a safer working environment for employees.

Emergency response

Emergency response plays a pivotal role in mitigating the consequences of lathe accidents, minimizing injuries, and ensuring the safety of operators and workplaces. It encompasses a comprehensive set of actions and procedures implemented in the immediate aftermath of a lathe accident to stabilize the situation, provide medical attention, and prevent further harm.

The connection between emergency response and lathe accident is inseparable. An effective emergency response can significantly reduce the severity of injuries and save lives. For instance, immediate first aid, such as controlling bleeding and stabilizing the injured operator, can prevent life-threatening complications. Prompt evacuation from the hazardous area minimizes the risk of further injuries or exposure to harmful substances.

Real-life examples abound, demonstrating the critical importance of emergency response in lathe accidents. In one instance, a lathe operator suffered a severe hand injury when their hand became entangled in the rapidly spinning chuck. Thanks to the swift and coordinated emergency response, the operator received immediate medical attention, preventing amputation and ensuring a successful recovery.

Understanding the connection between emergency response and lathe accident has practical applications in various domains. It informs the development of comprehensive emergency response plans, which outline clear roles and responsibilities for responding to lathe accidents. It also guides the provision of appropriate training to employees, ensuring they are equipped with the knowledge and skills to respond effectively in emergency situations.

In conclusion, our exploration of lathe accidents has unveiled crucial insights into their causes, consequences, and prevention strategies. Understanding these aspects empowers us to mitigate risks, safeguard operator well-being, and foster a culture of safety in the workplace. Key takeaways include:

- Lathe accidents frequently result from mechanical failures, human error, inadequate training, and environmental factors, underscoring the need for comprehensive safety measures.

- The consequences of lathe accidents can be severe, ranging from minor injuries to amputations and even fatalities, emphasizing the importance of prioritizing operator safety.

- Effective prevention strategies encompass a holistic approach involving machine guarding, personal protective equipment, safe work practices, training, and regulatory compliance.

Lathe accidents are preventable, and every workplace has a responsibility to implement robust safety measures and training programs to minimize the likelihood of such incidents. By recognizing the significance of lathe safety, fostering a culture of risk awareness, and continuously striving for improvement, we can create safer work environments for lathe operators and protect their well-being.

- Hobby Lobby Wood Arch Backdrop

- When Does Peysoh Get Out Of Jail

- Brekie Hill Shower Leaks

- Ellen Makes Taylor Swift Cry

- Stuns In New Selfie

Lathe Machine Incident Video Explained Russian Lathe Machine Accident

Lathe accident YouTube

Lathe Catastrophe! YouTube