How To Choose The Right Aj Hammer For Your Needs

An aj hammer is a specialized tool used in construction and metalworking for driving nails and shaping metal. It is typically characterized by its curved claw at the back of the hammerhead, which can be used for removing nails or prying objects.

Aj hammers are particularly useful for tasks requiring precision and control, making them ideal for woodworking, carpentry, and fine metalworking applications. The curved claw allows for easy nail extraction and provides additional leverage for shaping metal. Historically, the aj hammer evolved from the traditional claw hammer, with the curved claw being a key development that enhanced its versatility.

This article will delve into the various types of aj hammers available, their specific applications, and the techniques for using them effectively. We will also discuss the importance of proper hammer maintenance and safety precautions to ensure optimal performance and longevity.

- Overtime Megan And Antonio Brown

- Skipthe Games El Paso

- Breckie Hill Showers

- Antonio Brown Megan

- Florida Baseball Coach Scandal

aj hammer

The aj hammer is a specialized tool used in construction and metalworking for driving nails and shaping metal. Understanding the essential aspects of the aj hammer, such as its types, applications, and techniques, is crucial for its effective use.

- Types: Framing hammer, finishing hammer, ball-peen hammer, etc.

- Applications: Carpentry, woodworking, metalworking, DIY projects

- Techniques: Nail driving, nail removal, metal shaping

- Materials: Steel, forged steel, titanium

- Weight: 8 ounces to 32 ounces

- Handle: Wood, fiberglass, rubber

- Head Shape: Curved claw, straight claw, ball-peen

- Safety: Wear safety glasses, use proper technique

- Maintenance: Keep clean, lubricate moving parts

- Brands: Estwing, Vaughan, Stanley

These aspects are interconnected and contribute to the overall functionality and effectiveness of the aj hammer. By understanding and considering these aspects, users can select the appropriate hammer for their specific needs, ensuring optimal performance and safety.

Types

The various types of aj hammers, such as framing hammers, finishing hammers, and ball-peen hammers, each serve specific purposes and are critical components of the aj hammer family. These types differ in their head shape, weight, and handle design, which directly impact their functionality and effectiveness in different applications.

- Taylor Swift Cry

- Khamzat Without Beard

- Breckie Hill Shower Video Leaked

- Nomi Mac Miller

- Peysoh Wallpaper

Framing hammers, with their heavier heads and curved claws, are ideal for driving large nails into framing lumber. Finishing hammers, on the other hand, have lighter heads and straighter claws, making them suitable for precision tasks such as setting finishing nails and trim work. Ball-peen hammers, with their rounded heads, are commonly used in metalworking for shaping and riveting.

Understanding the distinct characteristics and applications of each type of aj hammer allows users to select the most appropriate tool for their specific needs. This understanding is essential for achieving optimal results and ensuring safety during various construction and metalworking tasks. By matching the hammer type to the task, users can drive nails efficiently, shape metal effectively, and complete their projects with precision and accuracy.

Applications

The aj hammer finds its primary applications in the fields of carpentry, woodworking, metalworking, and various DIY projects. Its versatility and effectiveness in these domains stem from its ability to drive nails, shape metal, and perform a range of other tasks with precision and efficiency.

Carpenters and woodworkers rely on aj hammers for framing, nailing, and shaping wood. The curved claw of the hammer allows for easy nail removal and prying, while the weight and balance of the hammer provide optimal force and control. Similarly, in metalworking, aj hammers are used for shaping, riveting, and other tasks where precision and control are essential. DIY enthusiasts also find aj hammers indispensable for various projects around the home, from hanging pictures and shelves to assembling furniture and making repairs.

Understanding the applications of the aj hammer empowers users to select the appropriate tool for their specific needs. This understanding enables them to drive nails securely, shape metal effectively, and complete their projects with accuracy and efficiency. By matching the hammer to the task, users can achieve optimal results, reduce the risk of accidents, and enjoy the satisfaction of completing their projects with a professional touch.

Techniques

Understanding the techniques associated with using an aj hammer, such as nail driving, nail removal, and metal shaping, is essential for maximizing its effectiveness and ensuring safety during various tasks. These techniques encompass a range of skills and methods that enable users to perform specific tasks with precision and efficiency.

- Nail Driving

Nail driving involves using the aj hammer to drive nails into wood or other materials. Proper technique ensures that nails are driven straight and securely, without damaging the material or bending the nail. - Nail Removal

Nail removal involves using the curved claw of the aj hammer to extract nails from wood or other materials. Proper technique minimizes damage to the material and prevents the nail from bending or breaking. - Metal Shaping

Metal shaping involves using the aj hammer to shape metal, such as bending, flattening, or riveting. Proper technique ensures that the metal is shaped accurately and without causing damage or distortion. - Safety Techniques

Safety techniques are essential when using an aj hammer to prevent accidents and injuries. Proper technique includes wearing safety glasses, using the correct grip, and avoiding overexertion.

Mastering these techniques enables users to utilize the aj hammer effectively and safely in a variety of applications, such as carpentry, woodworking, metalworking, and DIY projects. By understanding the proper techniques, users can drive nails securely, remove nails efficiently, shape metal accurately, and complete their projects with confidence and precision.

Materials

The materials used in the construction of an aj hammer, primarily steel, forged steel, and titanium, play a crucial role in determining its performance, durability, and overall quality. These materials possess distinct properties that directly impact the functionality and effectiveness of the hammer.

- Steel

Steel is a common material for aj hammers due to its strength, durability, and affordability. It provides a good balance of weight, strength, and cost, making it suitable for general-purpose applications.

- Forged steel

Forged steel undergoes a forging process that enhances its strength and durability. Aj hammers made from forged steel are more resistant to wear and deformation, making them ideal for heavy-duty applications.

- Titanium

Titanium is a lightweight and strong material that is increasingly used in aj hammers. It offers a higher strength-to-weight ratio compared to steel, resulting in hammers that are lighter and easier to handle, while maintaining durability.

The choice of material for an aj hammer depends on the specific application and user preferences. Steel hammers offer a combination of strength, durability, and affordability, while forged steel hammers provide enhanced durability for heavy-duty tasks. Titanium hammers, on the other hand, offer a lightweight and strong option for users who prioritize maneuverability and reduced fatigue. Understanding the properties of these materials empowers users to select the most suitable aj hammer for their specific needs and applications.

Weight

The weight of an aj hammer, ranging from 8 ounces to 32 ounces, plays a crucial role in determining its functionality and effectiveness for specific tasks. The weight directly impacts the force, control, and handling characteristics of the hammer.

Lighter hammers, typically weighing between 8 ounces to 16 ounces, offer greater maneuverability and precision. They are ideal for delicate tasks such as finishing, trim work, and light carpentry. The reduced weight allows for more controlled strikes, minimizing the risk of damage to materials and providing greater accuracy.

Heavier hammers, typically weighing between 16 ounces to 32 ounces, provide greater force and momentum. They are suited for heavy-duty applications such as framing, demolition, and driving large nails. The increased weight allows for more powerful strikes, enabling users to drive nails into dense materials and perform tasks that require more force.

Understanding the relationship between weight and functionality empowers users to select the most appropriate aj hammer for their specific needs. By matching the weight of the hammer to the task at hand, users can achieve optimal performance, efficiency, and safety. For instance, a lightweight hammer is ideal for installing molding, while a heavier hammer is more suitable for driving nails into hardwood flooring.

Handle

The handle of an aj hammer, commonly made from wood, fiberglass, or rubber, plays a vital role in the overall functionality, comfort, and safety of the tool. The choice of handle material directly impacts the user's grip, swing, and ability to control the hammer effectively.

Wooden handles are traditional and widely used due to their affordability, durability, and shock absorption properties. They provide a comfortable grip and help reduce vibrations during use. Fiberglass handles, on the other hand, offer a combination of strength, flexibility, and lightweight properties. They are less prone to breakage and can withstand harsh conditions, making them suitable for heavy-duty applications. Rubber handles provide excellent grip and vibration damping, reducing fatigue and improving user comfort during prolonged use.

Understanding the characteristics of different handle materials empowers users to select the most appropriate aj hammer for their specific needs. For instance, a wooden handle is ideal for general-purpose applications, while a fiberglass handle is more suitable for heavy-duty tasks or when durability is a priority. A rubber handle is recommended for applications where user comfort and vibration reduction are essential. By matching the handle material to the task at hand, users can optimize their hammering experience, enhance safety, and achieve the best possible results.

Head Shape

The head shape of an aj hammer, which can be curved claw, straight claw, or ball-peen, is a critical aspect that determines its functionality and suitability for various tasks. Each head shape offers unique advantages and is designed for specific applications, making it essential to understand their distinct characteristics.

- Curved Claw

The curved claw is the most common head shape for aj hammers. It features a curved end that allows for easy nail removal and prying, making it ideal for general carpentry and construction tasks. - Straight Claw

The straight claw has a straight end and is designed for precision nailing and finishing work. It provides greater control and accuracy when driving nails into tight spaces or delicate materials. - Ball-Peen

The ball-peen head has a rounded end and is primarily used in metalworking applications. It is designed for shaping, riveting, and other metalworking tasks where a rounded surface is required.

The choice of head shape depends on the specific task and the user's preference. For general carpentry and construction work, a curved claw hammer is the most versatile option. For precision nailing and finishing tasks, a straight claw hammer is preferred. And for metalworking applications, a ball-peen hammer is the ideal choice. Understanding the distinct head shapes and their applications empowers users to select the most appropriate aj hammer for their specific needs, ensuring optimal performance and efficiency.

Safety

When using an aj hammer, safety should be a top priority. Wearing safety glasses and using proper technique are crucial to prevent accidents and injuries. Safety glasses protect the eyes from flying debris or metal fragments that may entstehen when striking the hammer against a hard surface. Proper technique involves holding the hammer correctly, using a firm grip, and striking the nail or metal with precision. Failure to follow proper safety precautions can result in serious eye injuries or other accidents.

Using an aj hammer safely requires wearing safety glasses and using proper technique. Safety glasses are essential to protect the eyes from potential hazards such as flying wood chips, metal fragments, or nails that may ricochet during use. Proper technique involves holding the hammer securely, with the thumb placed along the side of the handle and the fingers wrapped around it. Striking the nail or metal squarely with a controlled motion helps prevent glancing blows that could cause the hammer to slip and potentially injure the user or others nearby.

By following these safety guidelines, users can minimize the risk of accidents and injuries while using an aj hammer. Wearing safety glasses and using proper technique are essential components of responsible tool use and contribute to a safe working environment. Understanding and applying these safety measures demonstrate a commitment to personal safety and prevent avoidable accidents, ensuring a positive and productive work experience.

Maintenance

Proper maintenance of an aj hammer, which involves keeping it clean and lubricating its moving parts, is crucial for ensuring its longevity, performance, and safety during use. Regular cleaning and lubrication help prevent rust, reduce wear and tear, and maintain the hammer's functionality. Neglecting proper maintenance can lead to a compromised tool that is less effective, less durable, and potentially hazardous.

The moving parts of an aj hammer, such as the hammer head and the handle, require proper lubrication to minimize friction and ensure smooth operation. Without adequate lubrication, these parts can become stiff, making it difficult to swing the hammer and drive nails or shape metal effectively. Additionally, dirt and debris that accumulate on the hammer over time can clog its moving parts, hindering its performance and increasing the risk of accidents.

Real-life examples of maintenance practices for an aj hammer include regularly wiping down the hammer head and handle with a clean cloth to remove dirt and debris. Additionally, applying a thin layer of lubricant to the moving parts, such as the pivot point between the hammer head and the handle, helps reduce friction and prevents wear. By following these simple maintenance steps, users can extend the lifespan of their aj hammer and ensure its continued effectiveness and safety.

Understanding the practical applications of proper maintenance for an aj hammer empowers users to take proactive steps towards preserving their tool and enhancing its performance. Regular cleaning and lubrication contribute to a well-maintained hammer that is reliable, efficient, and safe to use. By incorporating these maintenance practices into their routine, users can maximize the value and longevity of their aj hammer, ensuring its continued usefulness for various tasks.

Brands

Within the realm of aj hammers, the brands Estwing, Vaughan, and Stanley stand out as reputable manufacturers known for their commitment to quality and innovation. These brands have shaped the landscape of aj hammers, offering a diverse range of products tailored to specific needs and preferences.

- Quality and Craftsmanship

Estwing, Vaughan, and Stanley prioritize quality in their aj hammers, using premium materials and meticulous craftsmanship. Their hammers are meticulously engineered to withstand heavy-duty applications and provide exceptional durability.

- Range and Variety

These brands offer a comprehensive range of aj hammers, catering to various applications and user preferences. From lightweight finishing hammers to heavy-duty framing hammers, they provide options for both professional tradespeople and DIY enthusiasts.

- Ergonomic Design

Estwing, Vaughan, and Stanley prioritize ergonomics in their aj hammer designs. They incorporate features such as shock-absorbing handles and contoured grips to reduce fatigue and enhance comfort during prolonged use.

- Reputation and Trust

These brands have established a strong reputation for reliability and performance. Their aj hammers are trusted by professionals and hobbyists alike, ensuring peace of mind and value for money.

By understanding the unique qualities and offerings of Estwing, Vaughan, and Stanley, users can make informed decisions when selecting an aj hammer that meets their specific requirements. These brands continue to drive innovation and excellence in the aj hammer market, providing users with tools that empower them to tackle any project with confidence and precision.

In conclusion, the exploration of the aj hammer in this article has provided valuable insights into its versatility, functionality, and significance in various domains. The key points highlighted throughout the article emphasize the importance of choosing the appropriate aj hammer for specific tasks, understanding proper techniques for effective use, and maintaining the tool for optimal performance and safety. These aspects are interconnected and contribute to the overall effectiveness and satisfaction derived from using an aj hammer.

As we move forward, the aj hammer will continue to be an indispensable tool for professionals and DIY enthusiasts alike. Its adaptability and durability make it a reliable companion for a wide range of projects. Embracing the knowledge and techniques outlined in this article will empower users to maximize the potential of their aj hammer and achieve exceptional results in their endeavors. By recognizing the significance of this versatile tool, we can harness its capabilities to shape, build, and repair our world with precision and efficiency.

- No Internet Connection Tiktok

- When Is Peysoh Getting Out Of Jail

- How To Open Bath And Body Works Hand Soap

- Skip The Games El Paso Texas

- Is Ddot And Dd Osama Brothers

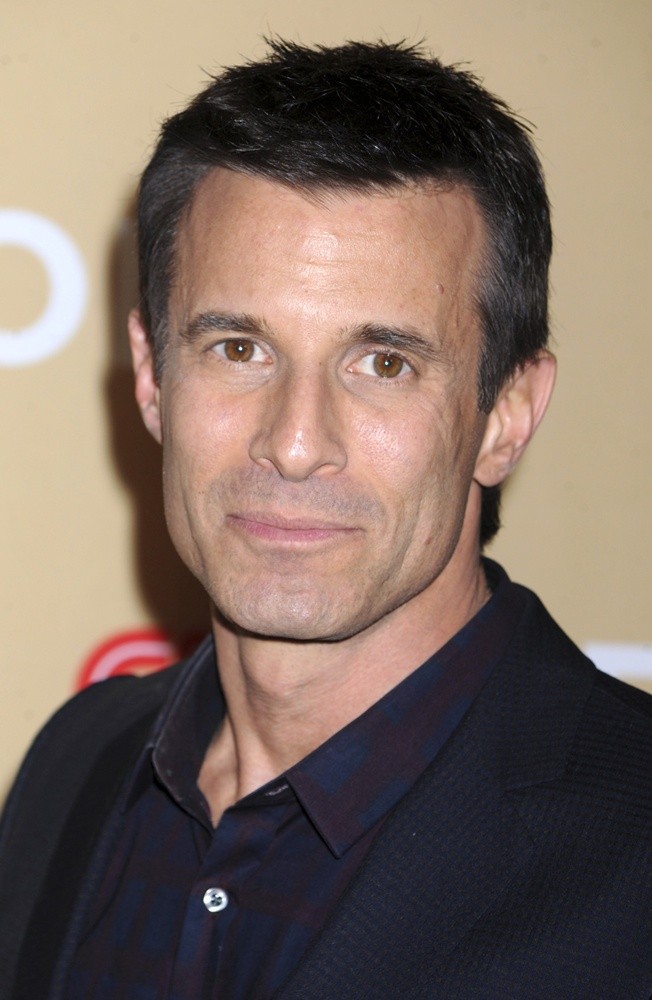

A.J. Hammer Picture 87 2013 CNN Heroes An All Star Tribute Red

A.J. Hammer A.J. Hammer photographed by Andrew Melick. Hos… Flickr

A.J. Hammer